Keep cell cultures viable, cell lines stable, and biologics abundant

To power the next generation of therapeutics, you need reliability in each bioreactor, each phase of your workflow, and each supply of reagents. Too often, researchers in upstream bioprocessing experience variability in buffer, culture conditions and supply chain, threatening protein or antibody yield and productivity.

As buffer experts and reliable providers that manufacture buffers and reagents in-house, we can help improve your upstream bioprocessing workflows and streamline the path to downstream purification.

How we simplify the process

As a leading manufacturer of buffers, reagents, and cell culture media, we have the expertise and resources to help you efficiently optimize and scale up your cultures and recombinant protein production. Our scientists go beyond providing the buffers and reagents you need to assist you in identifying the best growth and expression conditions.

Simplify your vendor relationships and raw material sourcing. We've established a network of reliable raw material providers and manufacture common and custom upstream bioprocessing buffers and media in house in our state-of-the-art facilities. When you partner with Boston BioProducts, you can simply move forward.

Ways Boston BioProducts can help:

Speak with an expert about your custom formulation

At Boston BioProducts, our experienced scientists are knowledgeable in identifying optimal pH and osmotic conductivity conditions for transfection reactions to create stable cell lines, and grow viable and healthy cultures. We provide personalized consultations to equip you with the tools for creating successful solutions that meet your ever-growing needs.

Improve reproducibility of upstream bioprocessing

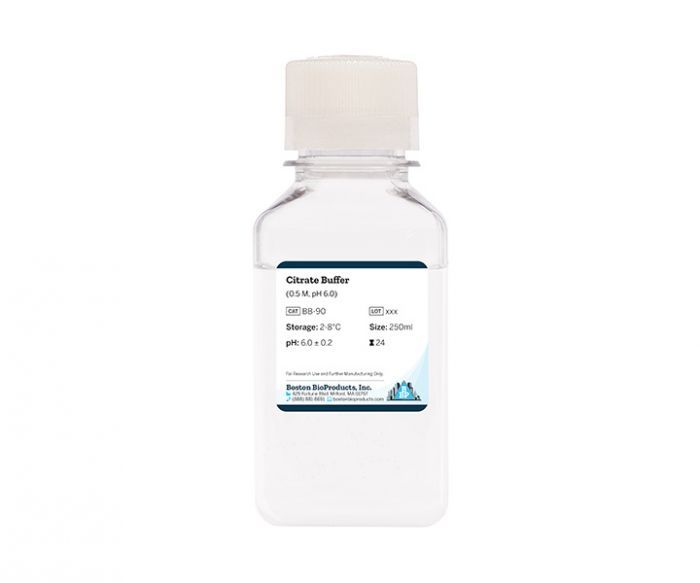

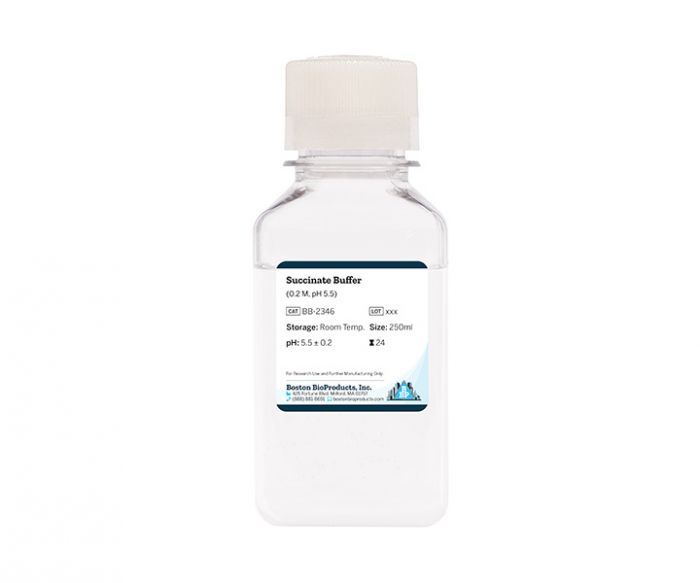

Our reliable buffer manufacturing system will eliminate the variables of inconsistent buffer conditions that may influence cell viability, expression, and yield. We deliver top-quality buffers by investing in fostering a culture of quality excellence, sourcing reliable suppliers and partners, and keeping meticulous records on each batch.

Learn more about how

Boston BioProducts can help

Featured Services & Resources

Certificate Request

Boston BioProducts is proudly ISO 13485:2016 certified and compliant. Our product offering follows GMP guidelines.

Quality Assurance

We formulate our pharmaceutical buffers with high-quality raw materials so you can confidently rely on our world-class products.

Order Support

Get tailored support to optimize your workflow. Let us serve you with our rapid communication, flexibility, and reliable supply chain.

Frequently Asked Questions

Upstream bioprocessing is essential in developing recombinant proteins, monoclonal antibodies, and other bioproducts. It involves growing healthy and viable cell populations for downstream bioprocesses. Upstream processes involve inducing the expression of proteins, monoclonal antibodies, DNA/RNA constructs, and more.

Bioprocessing involves manipulating living cells or components of cells to produce a desired product. Upstream bioprocessing typically includes culturing, inducing expression (e.g., through transfection reagents), optimizing cell growth and density, harvesting, and downstream processes such as protein purification and monoclonal antibody production.

Products made by bioprocessing include proteins, monoclonal antibodies, DNA/RNA constructs, and other bioproducts.

Organisms used in bioprocessing can range from prokaryotes to eukaryotes. Prokaryotes, such as bacteria and archaea, can be used to express proteins and produce enzymes. Eukaryotic cells, such as yeast, plant, insect, and mammalian cells, are also commonly used.